RESEARCH

Discovering Structural and Computational Mechanics

PROJECTS

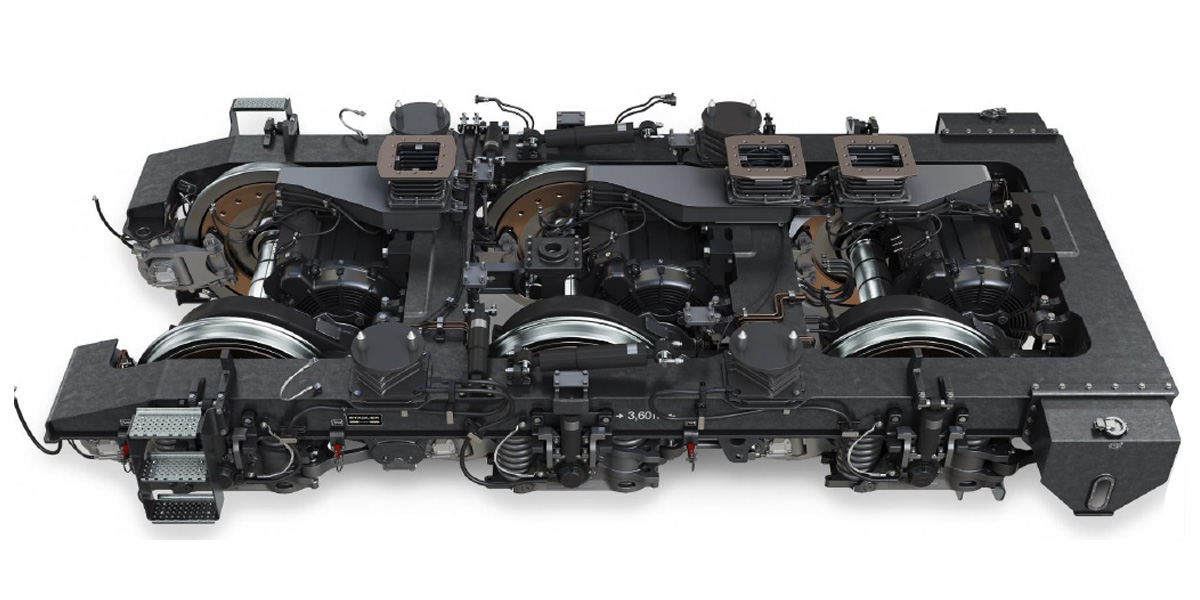

Project Acronym: LOCATE

Project Title: Locomotive bOgie Condition mAinTEnance

Responsible @ACMEC: Jorge Ambrósio

Participants @IST: António Andrade (ACMEC); Virginia Infante (ACPMME)

Other partners: Evoleo (Pt); FGC (Sp); UHuddersfield (UK); Vibratec (F); UIC (F).

Funding Institution: EU (Shif2Rail)

Project Reference: S2R-OC-IP5-01-2019

Funding: 220 k€(IST/IDMEC); 1500 k€(Total)

Duration: 36 months starting November 2019

URL: locate-project.eu/

Summary:The aim of this project is to provide the methods and tools by which every Entity in Charge of its Maintenance (ECM) to implement predictive maintenance of bogie, which is one of safety-critical component in a rail vehicle, in order to: (1) Ensure safety. The parts concerned are continuously under surveillance; (2) Increase availability and reduce cost by avoiding unnecessary controls. Most checks do not result in repair or replacement. The data collected makes a continuous improvement of the maintenance process easier to implement; (3) Increase reliability. Interventions are made before any problem in operation; (4) Without impact on maintainability. The implementation of surveillance equipment will be done under the control of the people doing the maintenance. The main objective of the LOCATE project is to replace as necessary as possible the preventive conditional or scheduled maintenance of mechanical parts of the bogie by predictive maintenance. It is expected that a condition-based monitoring maintenance program will: (a) Increase of availability (concerns only the time to work on the bogie) 30%; (b) Decrease of the costs (only the maintenance costs of the bogie) 20%; (c) Increase of the reliability (of the bogies and the components linked) 60% (incidents per unit of route). At the end of LOCATE we will have developed tools and methods to identify the failures in the bogies, primary and secondary suspensions, wheels, electric traction motor, or transmission. We will be able to anticipate these failures from several days to several weeks and to do pre-operational and operational planning using the data produced LOCATE will have developed all the tools and components to perform a demonstration on a locomotive and in a maintenance depot environment, providing decision-making information to the operator. The technology readiness level will therefore be TRL6 (technology demonstrated in relevant environment).

© Copyright 2020. All Rights Reserves.

Scientific Area of Structural and Computational Mechanics (ACMEC)